Acoustic cameras in machinery construction

The reduction of sound emissions is becoming increasingly important in the development of machinery. The use of sound pressure level meters enables one to determine whether a product or process complies with the legally prescribed limits - but what to do if that is not the case?

- Where do you start looking?

- Which component is causing the problem?

- Is a machine housing needed?

Seven Bel's acoustic camera, the Sound Scanner P132, allows machine builders to locate disturbing noises during development and on existing equipment. This makes it easier to implement targeted measures to sustainably reduce noise levels. In our User Report - Mechanical Engineering, the Upper Austrian special machine builder Fill GmbH describes how this technology is used within the company's environment.

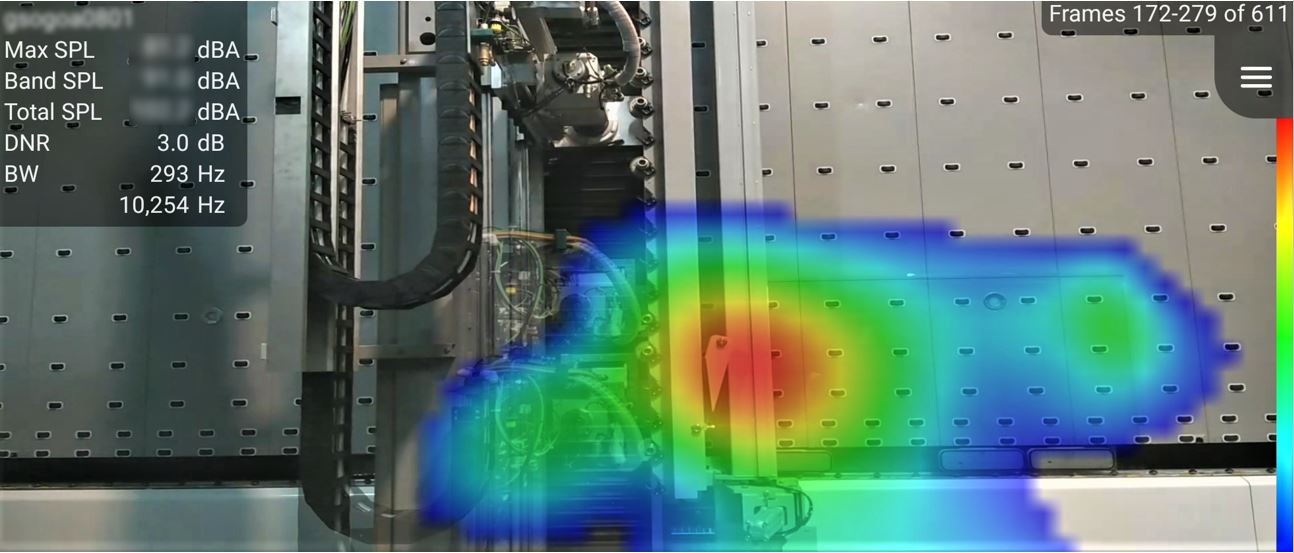

Machining Centers

By visualizing the local sound radiation during a machining process, noise-optimized machine housings can be designed.

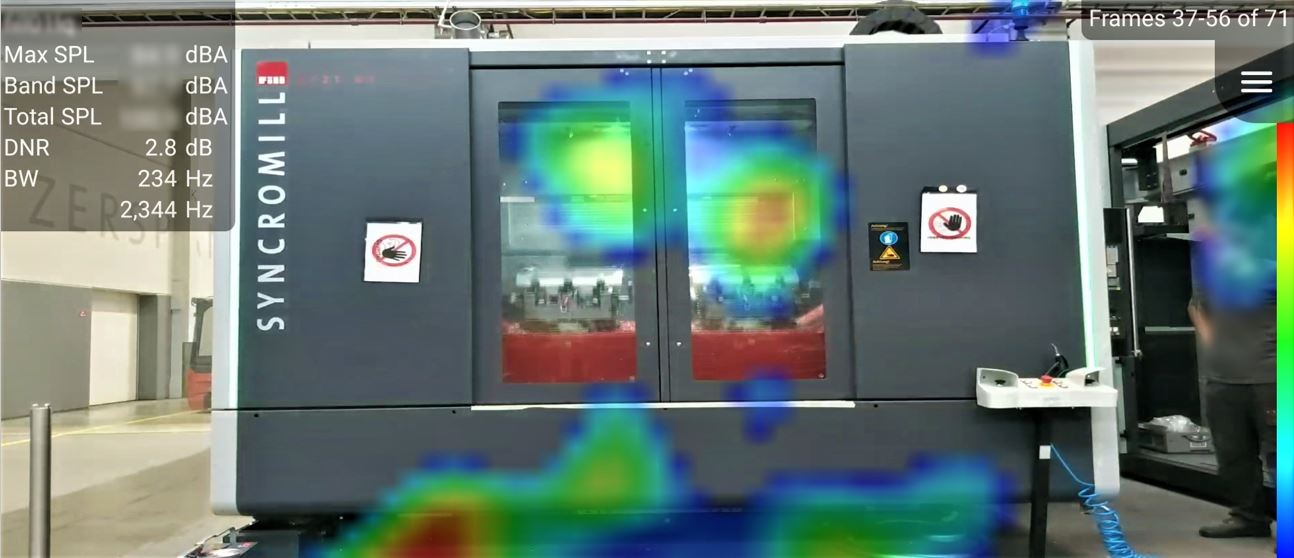

Special Purpose Machines

The localization of acoustic leakages simplifies the identification of necessary insulation measures. Dominant sound sources during operation are made visible and can thus be reduced in a more targeted manner.

Production Plants

Disturbing sound emissions are also not uncommon at other production plants. An analysis with the assistance of sound scanners can provide information about deficiencies and potential for improvement - here, for example, at a plant for the production of biogas.